Project Overview

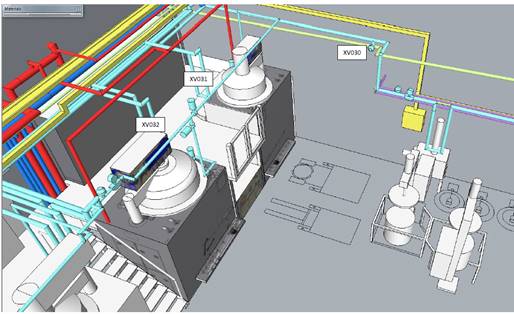

Esteé Lauder required an existing Purified Water Loop to be modified to accommodate the installation of two new processing vessels. The scope included new pipework sections for both CIP and Process water complete with new minimum dead leg addition points.

The key challenge was to deliver a design that met both performance and regulatory requirements. The proposed modifications had to be applied with minimal disruption to existing operations.