Project Overview

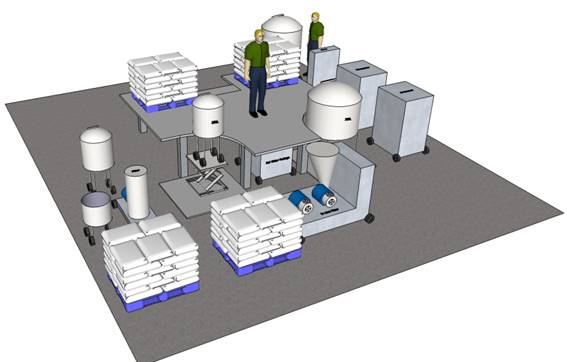

OLG BPE’s confidential client wanted to assess the impact of an increasing number of products vs smaller production volumes. Existing process equipment was scaled for larger manufacturing volumes resulting in significant product wastage and inflexibility.

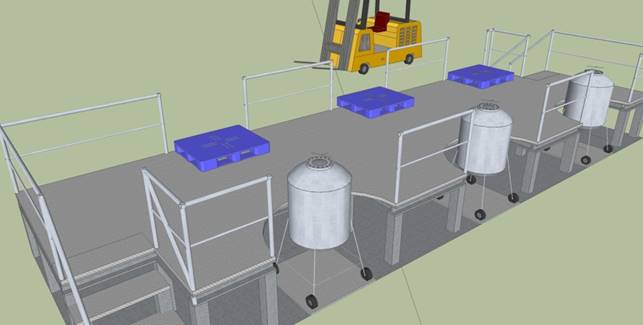

A new manufacturing concept was required but it was critical for this to be fully optimised in terms of both Capital and Operating Costs to meet the business case. The design required an appraisal of production volumes and the integration of a range of batch sizes into a flexible manufacturing model based on speed of product change and high yield operation.